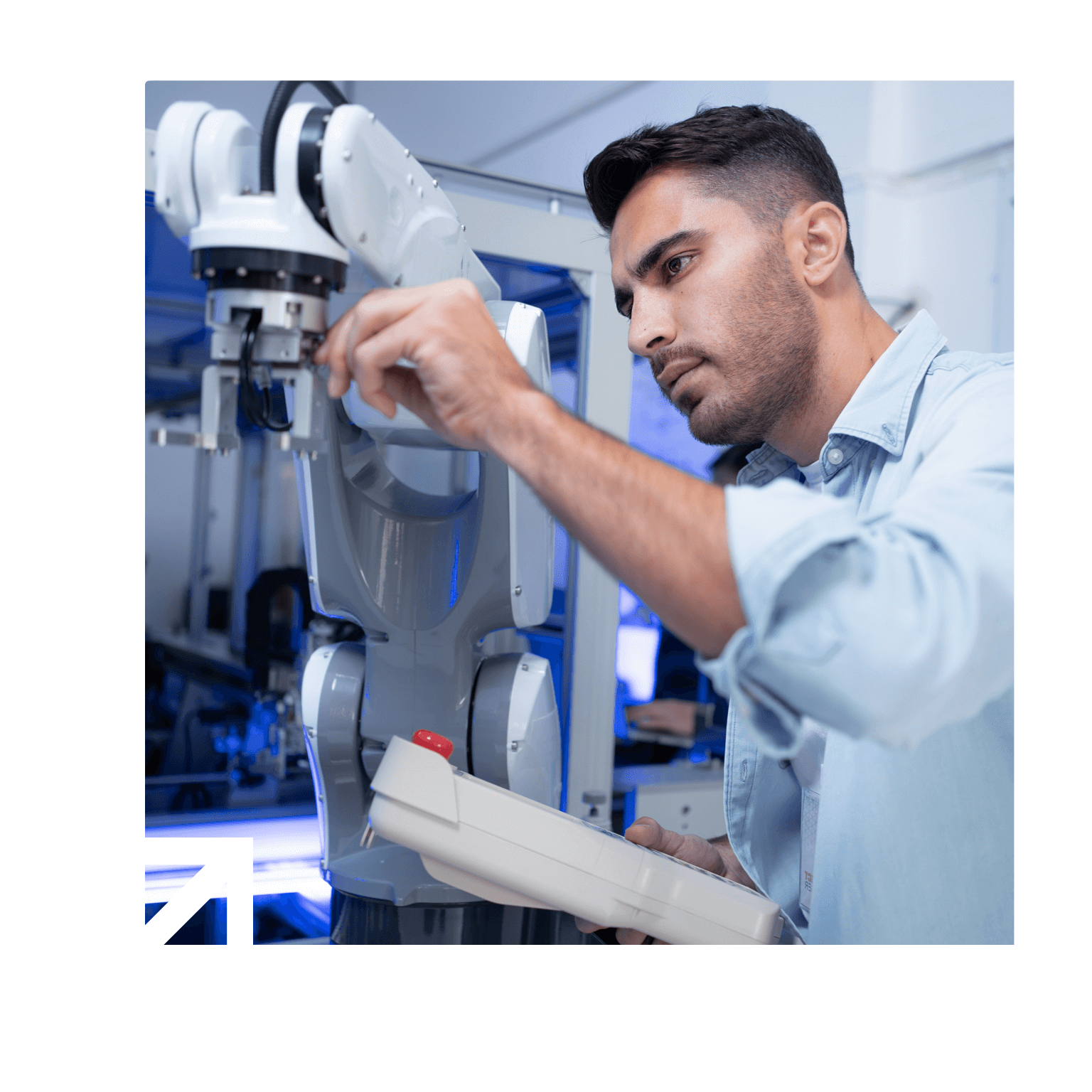

Manufacturing and Robotics Technicians install, configure, operate, and troubleshoot issues related to various manufacturing robots and related equipment. This role demands regular maintenance, system upgrades and prompt attention to malfunctions or breakdowns to minimize operational downtime. Technicians program and calibrate robots to meet specific production requirements and collaborate with engineers and other technicians to optimize robotic processes and to integrate new technologies.

Adaptability, Basic Computer Competencies, Communication, Creative Thinking, Critical & Analytical Thinking, Customer Focus, Dependability, Detail Orientation, Humility, Initiative, Instruction/Teaching, Integrity, Interpersonal Competencies, Leadership, Lifelong Learning, Mathematics, Problem Solving/ Decision Making, Professionalism, Reading, Scheduling/Coordinating, Science & Technology, Teamwork & Writing

Can identify basic mechanical problems and follow simple troubleshooting procedures

Strong Documentation Skills

Can effectively troubleshoot mechanical problems, analyze symptoms, and identify root causes

Possesses in-depth mechanical troubleshooting expertise, using advanced diagnostic techniques and specialized tools to resolve complex mechanical issues

Can understand basic electrical and electronic concepts and identify simple electrical faults

To be a Manufacturing and Robotics Technician, you need at least a high school diploma, with relevant coursework often preferred depending on the opportunity. Other preferred and/or required certifications include: Certified Production Technician (CPT), Certified Automation Professional (CAP), Certified Robotics Technician (CRT), OSHA Safety Certification, Lean Six Sigma Yellow Belt, Associate Certified Electronics Technician (CETa), Electrical certifications.

Check out our Career Resources Directory to find programs in Indiana that offer opportunities to develop your skills. These include certificate and degree attainment, internship programs, and mentorship to help you prepare for a career in tech.