IVM is again disrupting the industry it invented 25+ years ago

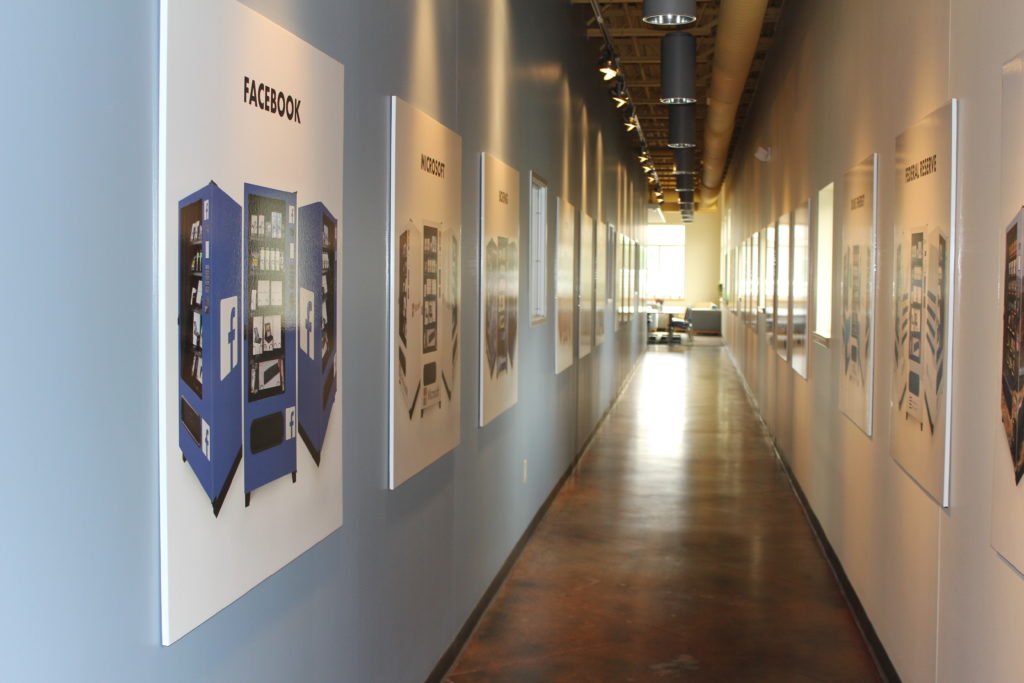

IVM, Inc. is an unlikely darling of the Silicon Valley set. While the Indianapolis-based smart vending manufacturer is a hit with decision-makers and companies of the actual Southern California tech scene, IVM also is literally on the Los Angeles stage set of the critically-acclaimed HBO series Silicon Valley.

“Every season, the set is completely redesigned based on where Pied Piper is in their journey, and the last season ended with them moving into huge new offices,” said Kyle Smallegan, director of marketing and communications at IVM. “The producers are big on authenticity so they scoured a bunch of similar-sized tech firms—and I think nearly every one of them was a customer of ours—so they told us they have to have our vending machines on set.”

The custom designed, vinyl-wrapped smart vending machines from IVM are actually part of the culture at many tech companies in Silicon Valley and around the world. Whether it’s personal protective equipment, maintenance, repair and operations products, or IT and office supplies, employees simply swipe their badges and punch in the code for the supplies they need. “Our machines now serve as an enterprise IoT solution, providing real-time reporting on stock and supply usage,” said IVM Inc. president Mike Pitts to Vending Times magazine. “IVM technology uses machine learning to predict and automate reordering, which provides companies with data that helps them make smarter decisions on how they are spending money on supplies.”

With high-profile customers like HP, Intel, Uber, Netflix, Hulu, Facebook and Dropbox, just to name a few, it’s hard to imagine IVM isn’t more well known here in its home town. IVM has 200 customers in all 50 states and 44 countries around the world. Surprisingly, the company does it all with fewer than 50 employees at its Northwest side headquarters, but that may change in the near future as new innovations drive expanded lines of business for IVM.

“We’re one of those companies people don’t hear much about around here unless they do business with us or have some other direct connection,” Kyle said. “That will start to change, however, as smart vending becomes more pervasive and people are seeing our Smart Stations at work, at school, or in retail stores and interacting with them themselves.”

Machine vending is a nearly $30 billion global industry and smart vending accounts for more than $6 billion, with a growth rate of about 11%. Vending machines hold a lot more than soda and snacks these days, and IVM is one of the leaders in distributing workplace essentials like keyboards and cables, as well as replacement or loaner laptops. The opportunity for IVM is significant, not just due to the industry growth, but because the majority of the market is still learning about the benefits of automated supply management and IVM is competing with manual inventory control as much as they are with other smart vending suppliers.

Kyle recounted a story with a major financial consulting firm where IVM’s main contact posted a photo of their new smart vending machine on Slack and within hours they had order requests from all over the world across the enterprise. “As we always say, if you hand out anything to anybody, we can do that better for you,” Kyle said. “We have case studies where we’ve trimmed distribution and tracking down from 15 minutes to just seven seconds. So it’s as much about creating a frictionless environment as it is inventory control and cost savings.”

IVM was one of the first companies to really disrupt the supply management process when it partnered with a railroad company to better control the distribution of gloves, hard hats and other safety supplies. IVM invented this niche of the vending market in 1993, and the company has continued to reinvent it every few years as new technologies and capabilities have allowed for new innovations and better outcomes for users and bigger cost savings for customers.

IVM is, in fact, in the testing or pilot phase with retail and university customers to revolutionize the way they sell and distribute products and supplies. Once the testing and pilots are completed there is a high likelihood that IVM is going to be hiring in all departments to keep up with the demand generated by the results they produce for customers.

While competitors have machines that ostensibly do the same things, it’s what IVM does on the back end with software and data that sets it apart. IVM customers can actually manage inventory and control their own data through a customized, real-time portal, whereas competitors might send reports once a month, Kyle explained.

He expects to ramp up more marketing efforts to support the IVM sales team through the rest of the summer and fall and be in a better place with IVM’s brand name recognition when Silicon Valley debuts its